![AquaDNA[tm]-HIGHRES-JPEG AquaDNA[tm]-HIGHRES-JPEG](https://deragger.com/wp-content/uploads/2018/09/AquaDNAtm-HIGHRES-JPEG-600x180.jpg)

Jacobs have developed an asset management platform – AquaDNA™ – to provide Operations and Maintenance teams with a greater overview of station performance.

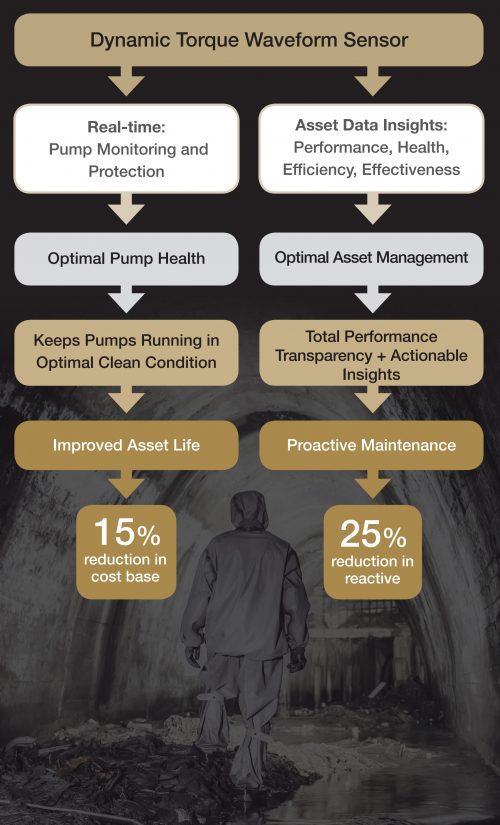

AquaDNA utilizes emergency technology of Dynamic Torque Waveform (DTW) analysis, coupled with real-time, predictive insights of lift station performance to continually monitor pump performance, health, efficiency, storm handling, and asset care, and has been proved to deliver 15% saving on cost of ownership as demonstrated in Jacobs’ recent white paper ‘Innovative technology reduces sewage pumping ownership costs by 15%’ which is to be published in Autumn 2019.

Save Money, Improve Performance:

- Baseline saving of 15% on the cost of ownership

- Dramatic reduction to reactive call outs

- You save from day one, becomes self-funding over a short period of time

You can read Jacobs’ recent white paper here.

A Helping hand for field teams:

- Better and safer working conditions.

- Less server pump problems and less time to address

- Less working over water or in confined spaces

- Fewer emergency overnight call outs

- Reduced interaction with contaminated materials.

AquaDNA gives you:

- Real-time and predictive insight to better manage your pump fleet in the near and medium term

- Allows the application of longer term asset management best practices that are driven by meaningful hard data

- Facilitates the move away from reactive maintenance and gives the opportunity to reshape how best to keep your lift station fleet in a healthy and robust state.

Do I need to replace my pumps?

No, AquaDNA:

- Integrates with current pumps / control panels.

- So no need to change pumps.

- Has intuitive interface, so learning straightforward

But do my pumps need DTW?

- Our research has found that many pumps suffer substantial loss of flow through undetected partial ragging.

- This often goes unnoticed as it is not enough to cause a pump to trip, and are not detected by telemetry.

Why do pumps need it?

- A pump operating in an unhealthy imbalanced condition will suffer more damage and wear more rapidly.

- If your pumps are under-performing on an ongoing basis and flow rates are reduced your lift station is at increased risk of being beaten by a storm, or worse losing station capacity through premature pump breakdown.

- Regrettably this hidden issue can be playing out undetected across the fleet, with even the ‘good’ stations affected.

So what exactly is Dynamic Torque Waveform (DTW) analysis, and what is AquaDNA?

- DTW technology, whose benefits have not previously been widely recognized, is a highly sensitive way to detect even small deviations from a pump’s optimal clean running state.

- Technology provider Clearwater Controls developed this technology originally to create their patented DERAGGER®+ solution.

- It works to prevent the buildup of debris in the pump through monitoring the variance in Dynamic Torque Waveform using smart machine learning algorithms and triggers early cleaning of the pump at the onset of any debris-related distortion.