The smart way to end ragging problems without changing or adding equipment.

"Using the DERAGGER we are saving over $1,200 per month, plus we can utilize staff for other activities instead of the constant pump cleaning."

"It is working great for us and we have not had any ragging issues on that pump since it was installed in 2014"

The DERAGGER LITE™ anti-ragging device solves the problem of wastewater ragging, clogs and blockages – so no more wasted manhours, damage to equipment, possible risk to employees and risk of overflow or spillages. By ensuring you constantly run a clean pump (or mixer, aerator etc.) it also prevents the negative impacts of running partially ragged equipment – such as vibration, decreased flow, longer run-times and higher power bills.

Our patented technology constantly looks for fluctuations in motor torque using voltage, current and speed. This enables the DERAGGER LITE™ to detect the first rags to get stuck. It then automatically runs a ‘clean cycle’, to pass the rags through.

The compact DIN-rail mounted unit (approximately 4″ x 5″ x 1.5″) is compatible with all starter types and is easy to retrofit.

-

The DERAGGER LITE™ anti-ragging device will eradicate pump clogs in wastewater pumps

-

Typical payback in 3-4 months

-

Reduces or eliminates operational callout costs

-

Improves electrical efficiency by up to 48%

-

Reduces spills and polluting incidents

-

Minimal interruption to ‘live’ sites

How does it work?

The DERAGGER LITE™ constantly monitors the torque signature of a pump’s motor, and can dislodge and pass rags in Real Time should they become stuck on or inside the impeller/volute. This is achieved with a tuneable “clean cycle” involving a brief and unique series of forward and reverse motions of the impeller.

But won’t reversals damage my pump?

Our unique technology reverses a pump BEFORE a clog is allowed to form, meaning pump reversal is completely safe. Trying to run pump reversals through other methods (such as programming a VFD) will mean pumps could reverse when already clogged which COULD damage your pump! Most quality pump manufacturers have endorsed the DERAGGER and provided reversing guidelines.

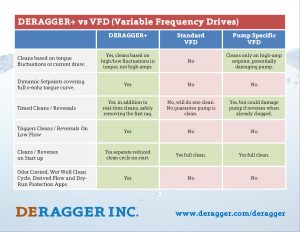

DERAGGER+ v VFD Comparison:

(Click to view PDF version.)

Timed v High Current Set-point v Real Time Reversal:

(Click to view PDF version.)